Duplex Brass Worm Gear

As one of the brass worm gear manufacturers, suppliers, and exporters of mechanical products, We offer brass worm gears and many others.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of brass worm gear.

Duplex Brass Worm Gear

The brass worm gear is a kind of gear made of brass. Brass is a soft metal, easy to work with, and has good wear resistance. The worm gear is used to transfer power between two misaligned axes. The worm gear has spiral teeth meshing with the worm gear teeth. Worm gears are usually made of harder materials, such as steel, to reduce wear and tear.

A double-guided brass worm or double-guided brass worm is a brass worm gear set in which the two flanks are manufactured with slightly different modules and diameter dealers. Therefore, different lead angles are obtained on the two tooth shapes, so the tooth thickness increases continuously over the whole worm length, and the clearance between the two threads decreases. This will control the rebound.

In worm gear, the different modes lead to the difference in the modification coefficient and the diameter of the rolling circle. Because of this, the sides on the front and back are others. The thickness and backlash of each tooth remain constant around the wheel.

Adjust The Backlash Of Worm Gear:

The backlash is adjusted by moving the worm towards the axis so that the portion of the worm with the desired tooth thickness is in contact with the wheel to generate the desired backlash (Figure 1).

This way, when the gear is installed, the clearance can be easily adjusted to any desired value. Even worn gears can be adjusted accurately and continuously without changing tooth contact or creating meshing interference.

In addition to the above duplex method, there are many ways to adjust the backlash of worm gear:

The center distance is changed by rotating the eccentric hub, in which the worm shaft and the seat are fixed

Axial displacement of conical worm (FIG. 2a)

Divide the worm into two halves (Figure 2b) and rotate or move relative to each other. (System Ott)

Divide the wheel into two disks (Figure 2c) so that they turn close to each other.

We are one of the best brass worm gear suppliers. We can offer wide brass worm gear stock. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

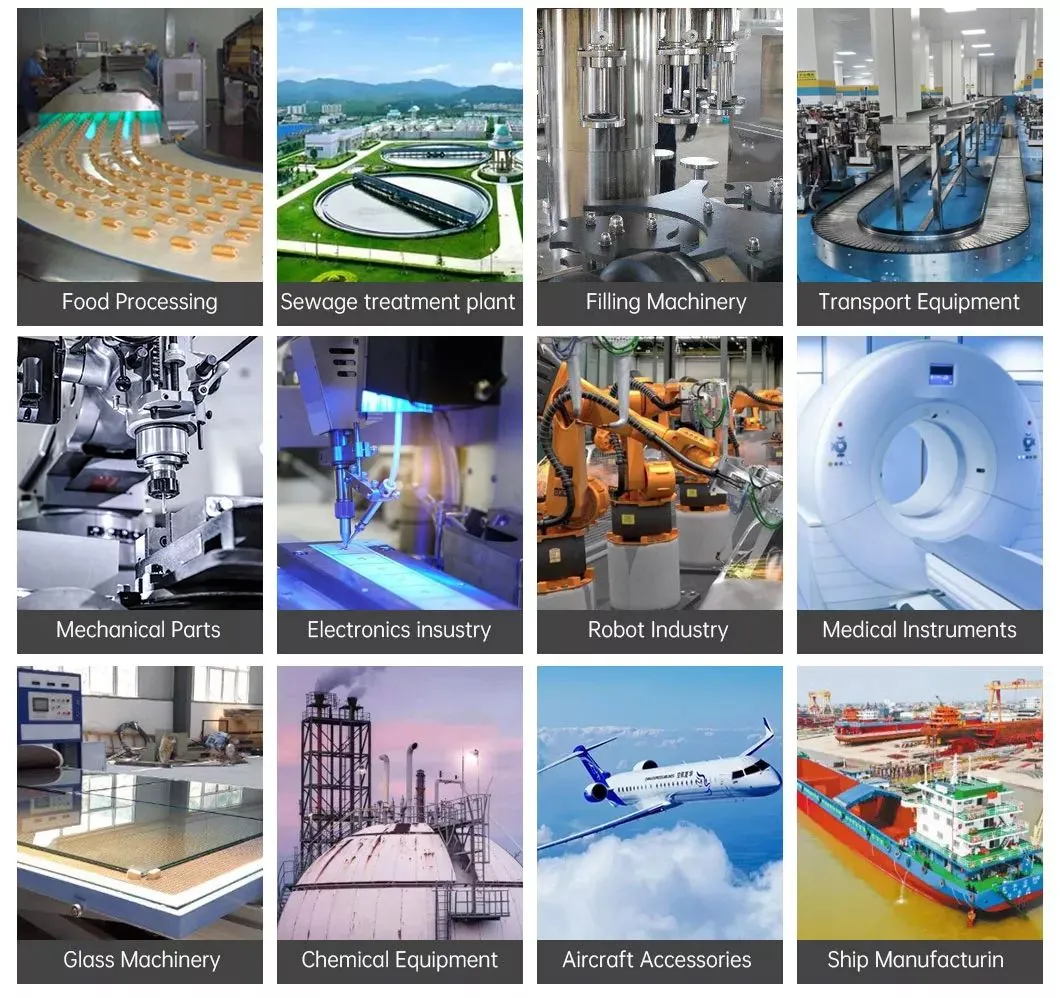

Brass Worm Gear Application: